One step spraydrying

One step spraydrying

Spray drying is the working horse in the world of drying. It can handle heat sensitive, non-heat sensitive and heat resistant pumpable feedstocks and turn these into a dry powder form. Many spray driers are installed in the world.

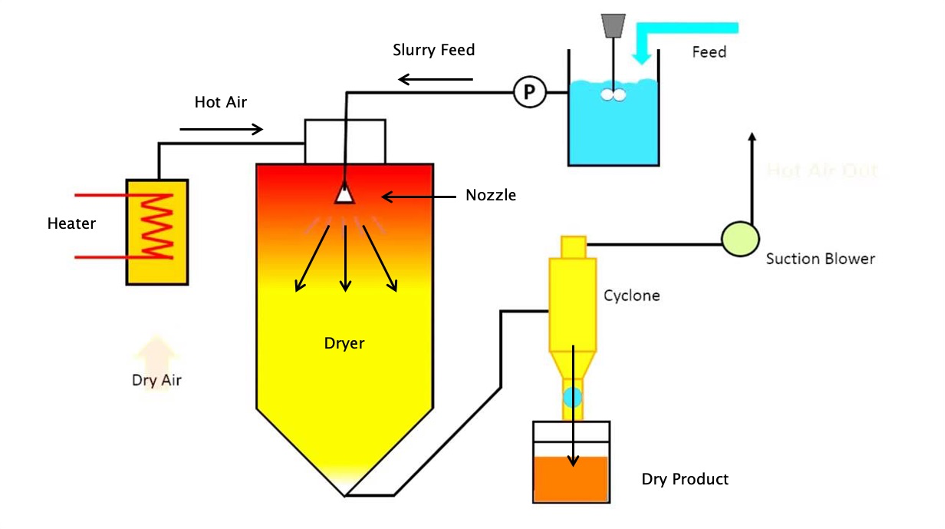

The majority of the products can be dried in one step. While being atomised into small droplets, it is exposed to hot air, evaporating at the spot. It is becoming dry at controllable temperatures.

Basically 4 phases can be distinguished

Atomisation

Contact between air and spray

Drying the spray

Separation of the spray

Characteristics of DW spray driers

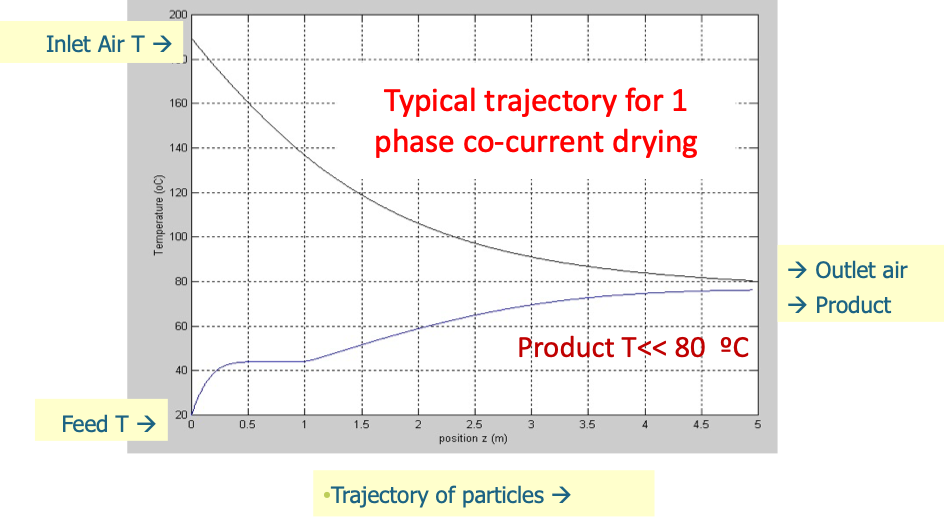

Co current spiral movement of the product and air transporting downwards. It keeps the product cooler than the air, at all places in the drier

High rate of drying thanks to the intense contact of air and droplets. Our Rota swirl air distributor is unique

Controllable particle size, shape, form, moisture content

Operation is preferable continuous by its controls

Handle wide range of production rates, turndown ratios

Handle for ST-1 explosive materials

Flexibility

Low fouling rate

High quality of functional proteins produced,

Completely electrical heating

Transportable by trucks

Special options DW spray driers

Low temperature de-humified air injection possible

Adding solid materials in the spray zone

Co-spray drying

Air dehumifier including air filtration